眾人期待的空氣汽水瓶即將登場了,它可以實現持續供應空氣的機能,安全又便宜,我試了很多種方法以及材質,最後終於找到一個最佳方案! 來看看這一連串的改變吧!

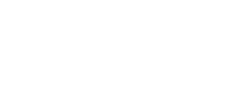

ver.1 (fig.1.) The connector is composed of a traditional cap and a washer. The airtight is incomplete and the cap could loosen up easily during movement. ver.3 (fig.3) A plug-shaped thingy is created, placed into the opening of the bottle, and fixed with 4 screws to keep the cap from loosening up.

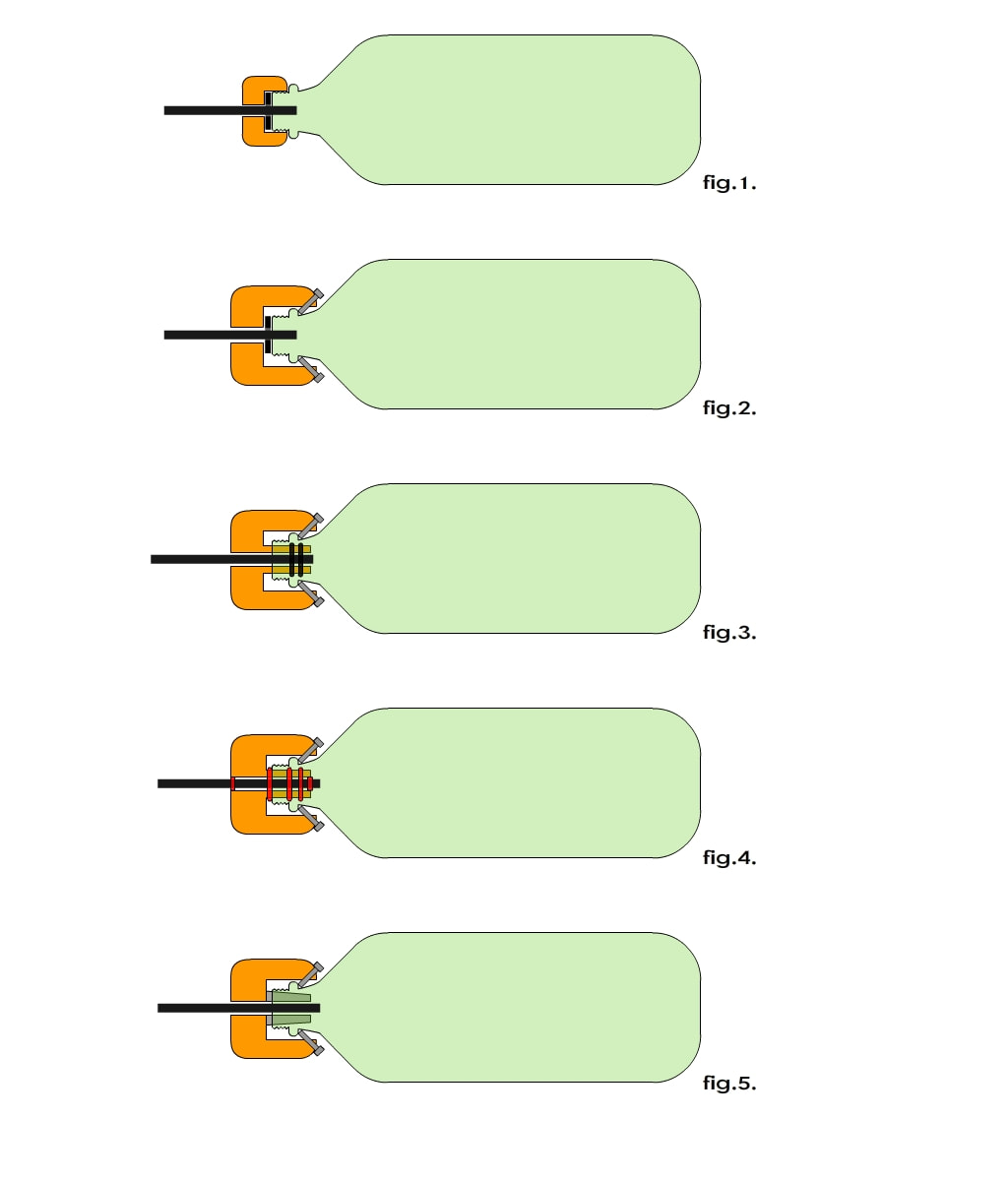

ver4 (fig.4) Replaced the material of O-ring with silicone rubber and achieved 99% airtight. However, air leaks from the contact surface between PU tube and 3D printed part. Though the contact surface could be glued to reach 100% airtight, it causes a lot of trouble. Eventually, ver5 (fig.5) is able to keep all air pressure from the surface of 3D printed part by plugging the bottle with a cork (rubber stopper) and inserting a PU tube to achieve 100% airtight.

Airtight can be completed with 3 silicone O-rings yet, the contact surface between PU tube and 3D printed part wouldn’t be sealed.

Airtight can be completed simply with a cork, followed by a 3D printed part to fix it in place.

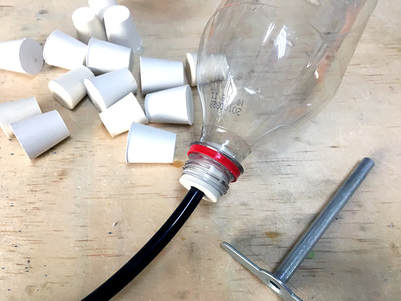

寶特瓶連接處為了搭配3D列印件,設計與一般的概念會不同,比方設計上零件避免也會避免使用支撐材料.

版本1(fig.1.)連接處為傳統的蓋子加上墊片,除了氣密不足,運動中容易轉開.版本3(fig.3.)將形狀往瓶口內塞,有如塞子的形式,並且用四根螺絲固定住,運動時不鬆脫.

版本4(fig.4.)將O-ring材質換成矽膠,達成99%氣密,但空氣會從PU管與3D列印的接觸面洩漏,可以用黏膠作為氣密,但是這相當麻煩.最終版本5(fig.5.)所有的空氣壓力不會與3D列印件接觸,方法使用軟木塞(像膠塞)塞住瓶口並且插入PU管即可完成100%氣密.

(fig.8.)為了美觀,我設計了將打氣筒往上移動的零件,稱為S路徑,原本採用3D列印100%填充,不過一樣無法達成100%氣密,因此更改使用氣動快速插PU氣管.

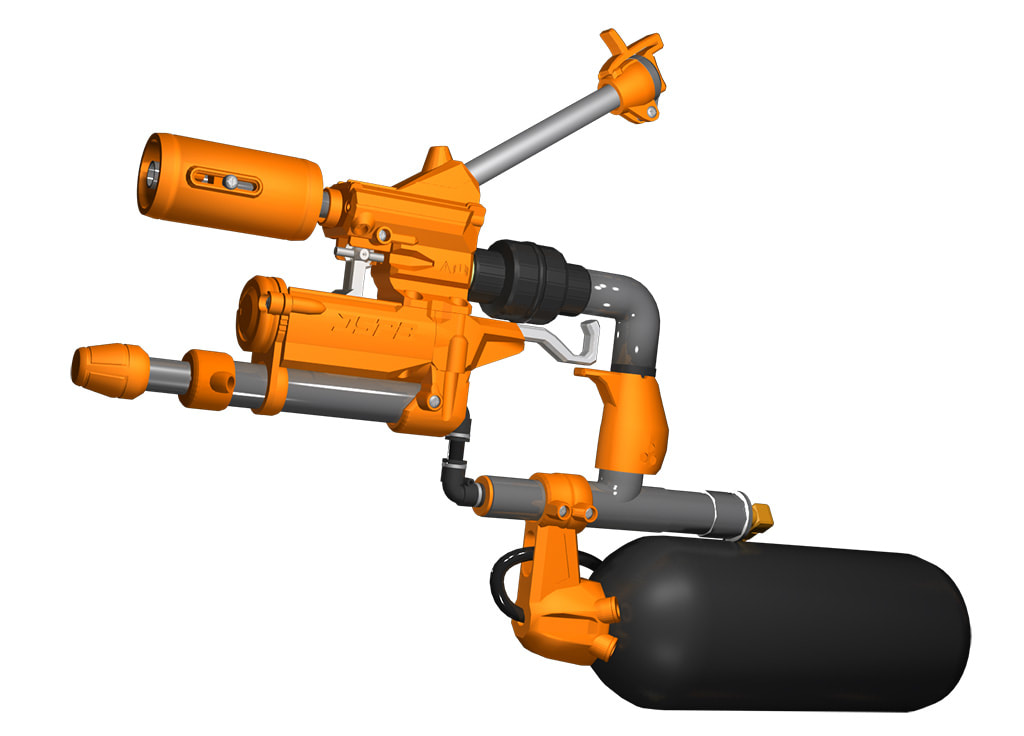

fig.9. 組裝完成圖 B&B Mini hopper+Mega tank+S-Path

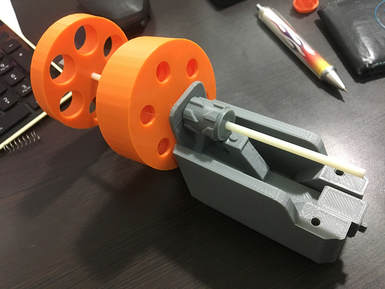

Mega tank研發告一個段落了,接下來是Cylinder了,下圖(fig.10.)是正在測試的原型,

利用扳機去推動Cylinder旋轉的原理,目前旋轉不夠流暢,目前正改進這個問題.

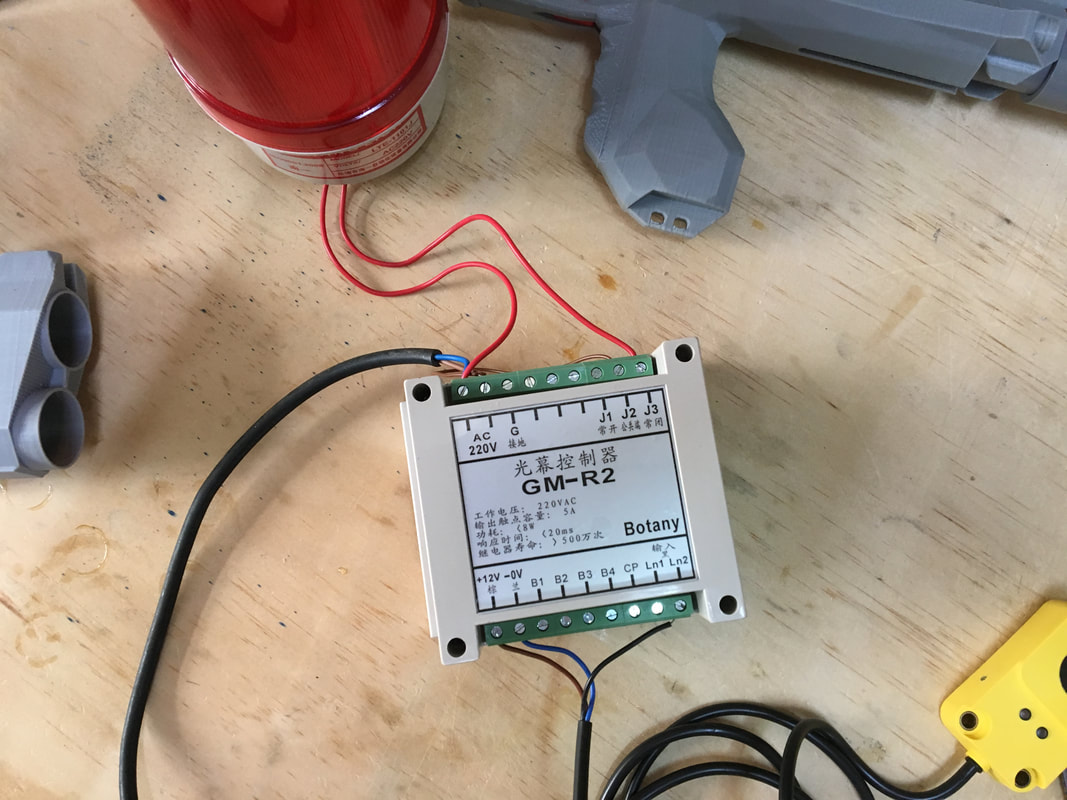

最後來聊聊其他的東西吧,首先是製造的部份,因為先前常常遇到filament沒了卻不知道的情況,因此安裝了光學斷線感測器,只要filament斷裂或是用完了,警報器就會響起,提醒必須更換.

再來是JSPB CHECK VALVE 3D,這個的設計理念很簡單,希望能讓人在家裡也可以列印出來的CHECK VALVE,你不需要去買很貴或是容易故障的CHECK VALVE,自己列印就可以了.

JSPB CHECK VALVE 3D 目前尚未完成,已經測試過許多材質與零件,現在可以得知的消息是,O-ring不可用,彈珠不可用,Nerf彈頭與軟木塞初步測試似乎可行,正要進入進一步的測試.

This is my recent progress and development for the last two months. Thank you!

以上就是這兩個月的研發進度,謝謝大家!

RSS Feed

RSS Feed